Fluid Power Machinery

Selected Research Projects

Optimization of the hydraulic Savonius Turbine

Responsible person: Dr.-Ing. Emeel Kerikous

This project aims at maximizing the output power of a hydraulic Savonius turbine by modifying freely the blade profile for difference concave and convex sides. Twelve geometrical parameters are involved during shape optimization. 636 transient computational fluid dynamics (CFD) simulations are performed using the industrial flow simulation code Star-CCM+. Finally, the optimized shape increases the performance of Savonius turbine by 15% compared to the standard shape. The Picture shows the pressure distribution around the optimized blade turbine at two different rotation angles. The video shows the velocity distribution and streamlines around the optimized blade for one complete revaluation.

Pitot Tube Pump: High Pressure Delivery and Adaptation to the Purification of Polluted Waters

Responsible person: M.Sc. Jessica Dafis, Prof. Dr.-Ing. Dominique Thévenin

The Pitot tube pump is a rather unknown centrifugal pump that works with low volumetric flow and high pressure. It is still used today in the purification sector of paper, food, and mining industries. Its design has not really changed over the 100 years since its development. Through the progress made in numerical methods, the optimization potential was identified and subsequently validated experimentally by industry partner bench tests. The properties of the characteristic Pitot tube are used to separate materials of different density from one another in a continuous process using a Pitot tube pump. The impeller maintains the pumping action in a manner that allows for simultaneous delivery and separation.

Figure: (left) Pitot tube pump setup purely for delivery; components with index ‘r’ rotate and index ‘f’ are stationary (right) Pitot tube pump adaptation for the continuous separation of two materials with different densities through centrifugal forces in the rotor

Figure: (left) Numerical simulations and (right) results of the first experiments using a prototype at the LSS with water and sunflower oil (Δ ρ≈70 kg/m3)

Figure: Grundidee und Forschungsergebnisse auf dem Weg zur funktionierenden Trennpumpe

Numerical Investigations and Optimization of Blood Pumps

Responsible person: M.Sc. Sebastian Engel

Blood as a medium poses great challenges to the design of blood delivery machines such as those found in operating rooms, dialysis, as well as in artificial hearts. This project examines blood pumps by modeling blood damage (mechanical hemolysis and platelet activation) and utilizing computational fluid dynamics methods. The goal is to develop methods and applications in order to improve existing types of pumps (via numerical optimization) as well as explore unusual designs. Axial pump designs have already been investigated and optimized in this endeavor. Furthermore, we participated in the FDA’s (Food and Drug Administrations) project “Critical Path – Blood Damage”.

Figure: Flow lines in the pump for the FDA’s „Critical Path“ challenge and pressure distribution on the rotor. Source: H. Yu, PhD “Flow design optimization of blood pumps considering hemolysis.”

Figure: Simulation of an axial blood pump. Shown are wall shear stress and the velocity distribution along flow lines.

Development of Modern Water Wheels

as part of the BMBF-funded “Growth Core Fluss-StromPlus” (project number 1714)

Responsible person: Dr. Olivier Cleynen

Nowadays, hydropower generation occurs mainly in connection with an obstruction of waterways. The operation of small-scale machines that function without congestion or obstruction — especially water wheels — is an environmentally friendly alternative. Such machines would bring our energy sector a step towards a sustainable, decentralized power grid.

The fluid mechanical consideration of equipment with a low velocity, a free surface without a dam system is, however, complex. The dynamics of two phases (air and water) need to be calculated in an unsteady, turbulent environment. 2D as well as 3D CFD models are being used in order to understand and characterize the influence of single blade geometry, rotor dimensions, or floating bodies. The numerical simulations are being carried out in parallel with experimental trials. PIV (Particle Image Velocimetry) measurements on a smaller scale model are being performed in the institute’s new water channel in order to calibrate and validate the numerical simulations. By recording parameters such as the increase in rotor power density, operation outside of the design points, tolerance of foreign bodies, and mechanical power output stability, this study shall lead to a quantitative description of the performance of modern hydraulic equipment operating at a free surface.

Figure: Velocity profile and water surface of a rotating water wheel prototype

Numerical and experimental optimization of a cross-flow tidal turbines

Verantwortlich: M. Sc. Karla Ruiz-Hussmann, M. Sc. Timo Bennecke, Dr.-Ing. Stefan Hörner

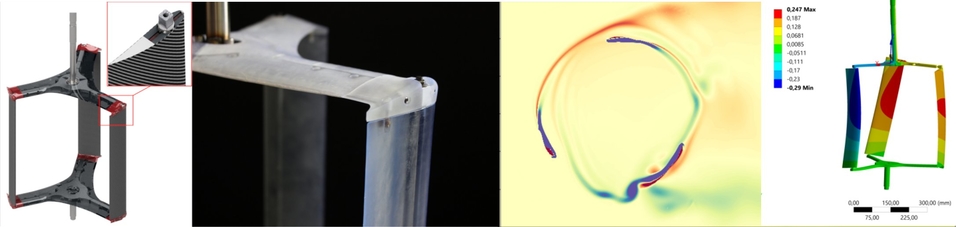

Cross-flow tidal turbines (CFTTs) also known as Darrieus turbines offer high area-based power densities, operate independently of the inflow direction and promise a cost-effectivve, robust and simple design. However, their rotation around the vertical axis results in high alternating loads and dynamic stall. This leads to reduced efficiency and a reduction of the turbines service life due to fatigue failure. One solution to this challenge is integrating pitching actuators into the blades,which allows to optimize the angle of attack throughout the cycle, enhancing the efficiency while lowering the alternating loads.

This project investigates the effect of variable pitch on CFTTs, aiming to find an optimal pitching law that maximizes the turbines hydrodynamic efficiency while minimizing the pitching actuation energy costs. The research combines experimental and numerical approaches. A turbine flume model is developed and equipped with pitching actuators and advanced instrumentation to measure the turbines performance, blade loads and mechanical stresses. This allows to conduct an experimental optimization using genetic algorithms to evaluate various pitching laws. A finite-element model of the turbine predicts the overall stress distribution giving a deeper understanding of the fluid-structure interaction. Additional Computational Fluid Dynamics (CFD) simulations in OpenFOAM allow to optimize the blade geometry and provide further insight into flow interactions an the entire flow field.

The project is an international cooperation between the Laboratory of Fluid Dynamics and Technical Flows and the Institute of Electrical Drive Systems at the OvGU Magdeburg as well as the Laboratoire des Écoulements Géophysiques et Industriels at the Université Grenoble-Alpes in France. The research is conducted as part of two German-French joint thesis (Cotutelle de thèse) with the Grenoble Alpes University. It is funded by the DFG and the LabEx Tec21, sponsored by the Franco-German University and a PhD scholarship from the graduate funding from the state of Saxony-Anhalt.

Figure:from left to right: (1) CAD Model of the developed turbine model, (2) detail of the 3D printed covers over the blade-support junctions, (3) vorticity field of the turbine acquired by 2D CFD simulations, (4) expected deformation of the turbine (increased by a factor of 86) acquired by FEM analysis.

Research project RETERO: Reduktion von Tierversuchen zum Schädigungsrisiko bei Turbinenpassagen durch Einsatz von Roboterfischen, Strömungssimulationen und Vorhersagemodellen" (Förderkennzeichen 031L0152A)

Responsible person: Dr.-Ing. Stefan Hörner, M.Sc. Dennis Powalla

The main goal of the RETERO research project is to minimize the use of live-fish in injury risk assessment in downstream turbine passages. Within this context, a new method shall be developed. This method will be based on experiments, complemented with partly-autonomous robotic sensor fish surrogates, as well as on numerical simulations, featuring a risk assessment with help of fish behaviour models and computational fluid dynamics (CFD).There are two major approach paths to this project at the laboratory.

The first is to minimize the injury and mortality rate by developing a prediction model. This model should forecast the movement of a migrating fish in a complex 3D hydrodynamic field and account for possible contacts between fish body and surrounding structures, such as moving turbine blades. The current approach is to develop a multi-agent system algorithm based on results provided by CFD simulations, where agents and associated behaviour response are derived from live-fish observations.The second part is involved in the development of a robotic fish surrogate. Forces acting on a moving fish body are assessed to gain information about the necessary forces of a propulsion device of a fish robot. The movement of the fish is realized by a morphing mesh model. The grid vertices morph to accommodate the body movement according to a predefined function in accordance to real fish motion characteristics.

Numerical Investigations of a Gravitation Water Vortex Power Plant as a Fish Ladder

as part of the BMBF-funded “Growth Core Fluss-StromPlus” (project number 1714)

Responsible person: Dr.-Ing. Nils Lichtenberg, Dr.-Ing. Stefan Hörner

The requirements for good water quality in Europe’s bodies of water also mean restoring the ecosystem and therefore allowing fish to freely migrate upstream and downstream. As a consequence, measures that are taken and structures that are built must allow for such migration. This project deals with the resulting geometric and hydraulic requirements for such structures. Based on simulation results, the suitability of a gravitation water vortex power plant as a fish ladder is underlined, since all the requirements for flow velocity are maintained. The system houses a complex, time-dependent vortex structure, which leads to constantly changing positions of the vortex core. In the optimization of computation times, an ongoing adaption of the mesh size is carried out. This results in a particularly good mesh density in areas with a high velocity gradient and the free surface.

Figure: left: schematic representation of the gravitation water vortex power plant, right: velocity profile with representation of the mesh refinement in areas with a large velocity gradients and the free surface.